Dustaway Auto Shake Filter Units

High Efficiency Dust Collection Units Designed To Suit Your Exact Requirements

Solutions

The Sangre DustAway Auto Shake series of dust extraction units are complete automatic dust collectors each contained within a single cabinet. They contain all the basic requirements of: –

- Fan

- Filter

- Hopper

- Bin

- Auto shake Starter supplied loose as standard

These units have been designed with maximum efficiency and durability as prime considerations.

By variation of filter fabric and disposal method each unit becomes tailored to the needs of the specific application so that an answer to your dust problem can probably be found within the DustAway range. Maintenance is carried out from the clean side of the filter media.

Typical applications:-

- Powder Coating Spray to waste and powder recovery

- Shot Blasting extraction

- Food Powders (Mixing/Packing)

- Chemical Powders

- Spring Grinding Extraction

- Wood Waste Machining Extraction

Legal

Despite the UK having left the EU those who have worked with the ATEX directive and the NFPA standards for combustible dust. Directors should evaluate and classify their working conditions to evaluate the risks. In addition all process and manufacturing equipment should meet the regulations concerning legal and technical standards.

Sangre dust extraction systems meet and exceed the requirements of these various directives when they have been designed, manufactured, installed and commissioned by ourselves.

For more details please do get in touch.

Additional Downloads

Health

A clean working environment helps promote high quality production.

A dust free environment is a great way to keep your premises clean and workers motivated.

Not having dust in the atmosphere improves health by stopping worker breathing in the particles of dust. Healthier lungs make for more productive workers who are more likely carry on working for your company.

Healthier workers are happier and are more likely to remain loyal employees, helping to reduce recruitment and training costs.

Efficiency

Cutting and working with wood is a classic example of a dust problem Sangre are familiar with working with and providing enduring solutions which minimize wood dust very cost effectively. In addition to operator health considerations many machines rely upon being operated in a dust free environment to maintain their accuracy. If there is a build of dust in the working area there is a high chance that accuracy can be affected and compromised. In addition to avoiding spoilt work – the warranty on machines frequently specify that they should be operated in a low dust environment.

Working with machines in a dusty atmosphere can affect bearings and sensors – with our Dustaway extraction system you can extend the working life of machines and the machine sensors.

Why not get in touch today to learn how Sangre can tackle your dust extraction issues.

Operational Details

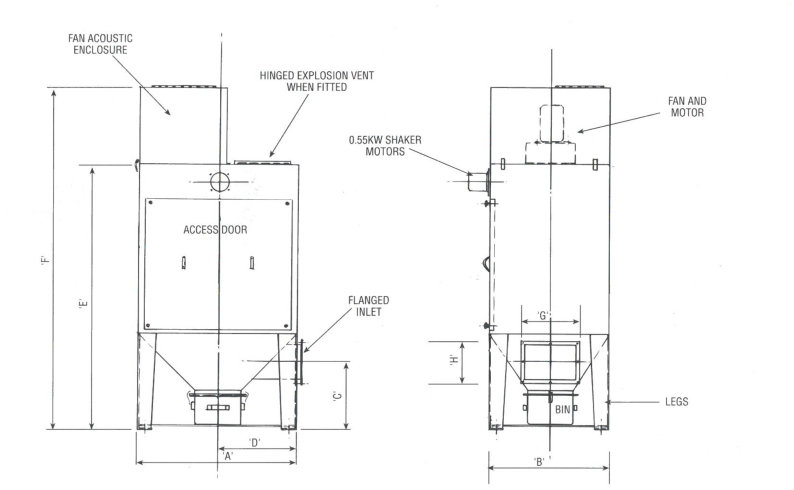

Dust laden air enters the unit through an inlet spigot located directly above the dust collecting bin. Large particles drop into the bin as the air enters the unit due to a drop in air speed and to the sudden change in flow direction. The air is drawn upwards through the filter bags where the fine particles are collected. Finally clean air is drawn into the fan and then discharged either back into the factory or to atmosphere.

The fine dust is deposited on the inside of the bag is dislodged after shut down of the fan by shaking so that the dust may fall into the collection bins. Shaking is carried out by an electric motor which is automatically actuated when the fan is de-energised and has been allowed to run down and stop. The dust collection bins may be removed for emptying by simply releasing the quick release and pulling forward.

Access to the filter element and shaker and mechanism for inspection and maintenance is through the large door on the front of the unit.

For most applications the fan is contained within an acoustic enclosure.

Secondary filter elements and enclosures are available.

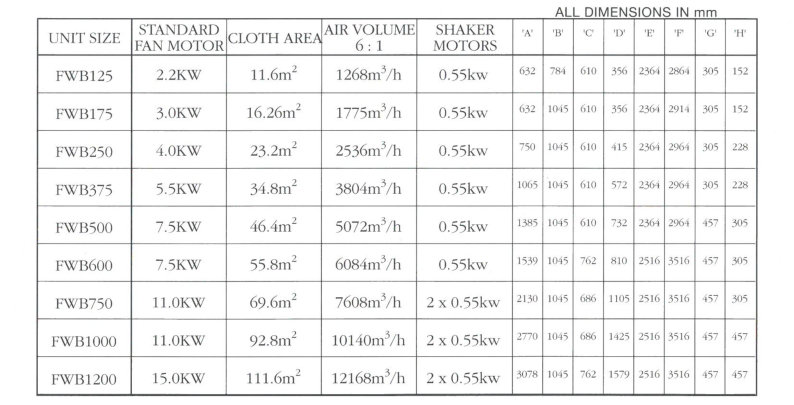

Sangre Dustaway Capacity Range

- Air volumes between 1000 m3/hr and 25,000 m3/hr

- Units from 5m² to 150m² filtration area.

- Integral fan & motor.

- Various filter media to suit your application.

Typical Applications

- Foundries

- Woodworking / Furniture Industries

- Automotive Industries

- Rubber Industries

- Food

- Spring Grinding

- Powder Coating

- Chemical

- All Types of finishing Industries

Technical Details